Call us +917276067892

Dear Customers, our deliveries are currently impacted due to Covid restrictions in various cities and states. Your orders may take longer than expected time to reach you.

Sohum offers complete services in custom mold design, and manufacturing, using materials such as Aluminium, Zinc, or other suitable materials with sufficient capacity for a wide spectrum of part dimension, and volume.

At Sohum, we integrate our in-house engineering and manufacturing capabilities for streamlined project progression. Our staffs’ engineers are well versed in managing the entire lifecycle of your die casting manufacturing project and can advise and consult with your team to improve the quality and reduce the cost of your parts.

Sohum’s overall project management ensures timely completion and high accuracy without exception. When you depend on Sohum as your die casting partner, every project is a success.

To supplement our die casting capabilities, we offer a full range of secondary finishing solutions. Sohum provides machining, finishing, assembly, and testing of all our die-cast projects.

Can your company benefit from die cast parts? You might be surprised. Die casting remains one of the most reliable methods for making metal parts, especially parts made from metals like aluminium, zinc and magnesium.

If your company uses metal parts and you’re not sure whether die casting is an appropriate way to build them, get in touch with us at Sohum Die Casting. Some of the common industries you may not have realized are often made using die casting include:

Die casting is often used to make components for the automotive industry or decorative hardware and many other small components. In fact, die-cast parts can be found in many things; you are probably just unaware that they are made from die-cast metal. Locks and gears are common finished products. Other examples are hooks, toys, door handles, pumps, power tool housing, golf clubs and general engineering castings.

They also make up the majority of products requiring the strength of a seamless metal part, like taps and pump handles. Other examples of die-cast products include engine fans, compressor valves and camera housings.

As a testament to the flexibility of the die-cast metal industry, our castings have been used in different sectors

This is in part due to the fact that die casting is an efficient, economical process that offers a broader range of shapes and components than any other manufacturing technique. Die-cast components also have a long service life and may be designed to complement the visual appeal of the product.

Product design engineers can benefit from the many advantages of specifying die-cast components as part of their next project.

Due to the flexibility and benefits of the die casting process, using it in your next product or component, decorative trim and/or finished products have many advantages:

Components are durable, dimensionally stable.

However, die casting is a high-volume production process, so part requirements need to be of a high enough volume per year in order to offset tooling costs.

If you are a product designer or part of a purchasing team and you are not sure or aware of the benefits of using die cast components in your next project then speaking to us directly about the possibilities is a good start, call us on 020-67500000/7276067892

We are the experts at making die cast parts. We have over 10 years of experience casting of durable components. We do everything in-house at our state-of-the-art facility to provide a turnkey solution to your die casting needs.

We are an ISO 9001:2015 certified company.

To find out about die casting products for your business, contact us online today at enquiry@sohumautogas.com.

020-67500000/7276067892

Don’t hesitate, you can get started with your project by speaking with one of our representatives.

Request a Quote or Give Us A Call Today!

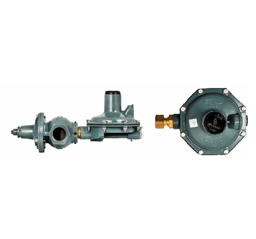

Domestic Regulator

Horizontal Version

Industrial Regulator High

GSD Vertical Version

Domestic Regulator

Industrial Regulator

Industrial Regulator